THERMATITE™

NEUFOAM™ INSULATED POLYURETHANE SECTIONAL OVERHEAD DOORS

Thermatite Door Systems are built stronger with Neufoam™ technology – a continuous foaming process that renders cavity-free sections. No air pockets inside the panel ensures superior adhesion of our CFC/HCFC-free polyurethane insulation to the steel skin, preventing delamination and providing exceptional structural integrity. The door has a higher strength-to-weight ratio, offers a better thermal barrier (higher R-Value) and resists deflection. Sections feature thermal breaks and two continuous replaceable seals to minimize air flow.

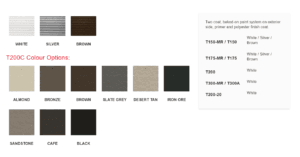

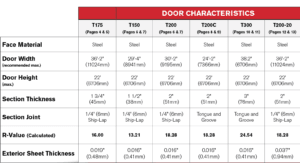

T150

- 1.5″ Neufoam™ Insulated Polyurethane Door

- Shiplap Section Joint

- Available in 3 colours and two panel styles.

T175

- 1 3/4″ Neufoam™ Insulated Polyurethane Door

- Shiplap Section Joint

- Available in 3 colours and two panel styles.

T200

- 2″ Neufoam™ Insulated Polyurethane Door

- Shiplap Section Joint

- Available in 1 colours and two panel styles

T200C

- 2″ Neufoam™ Insulated Polyurethane Door

- Tongue & Groove Section Joint

- Available in 9 colours and two panel styles.

T200-20

- 2″ Neufoam™ Insulated Polyurethane Door

- Featuring 20 Gauge Exterior Steel Sheet

- Shiplap Section Joint

T300

- 3″ Neufoam™ Insulated Polyurethane Door

- Tongue and Groove Section Joint

- Available in 1 colour and two panel styles.

Thermatite Door Systems

Installed with our highest quality hardware components, Thermatite Doors are engineered to provide many years of worry-free operation and are suitable for a wide range of applications.

SECTION DETAILS

COLOURS

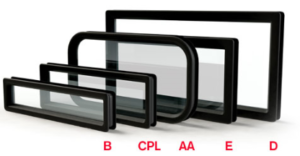

OPTIONAL GLAZING

Glazing Options:

| Type | Dimensions globales | Frame Colour | Description |

|---|---|---|---|

| B | 24″ x 6″ 610mm x 152mm | Black, White | Clear glass sealed unit set in moulded frame. |

| CPL | 24″ x 8″ 610mm x 203mm | Black, White, Brown | Clear glass sealed unit set in moulded frame. |

| AA | 26″ x 13″ 660mm x 330mm | Black, White | Dual acrylic unit set in moulded frame. |

| E | 24″ x 12″ 610mm x 305mm | Black, White, Brown | Clear glass sealed unit set in moulded frame. |

| D | 34″ x 16″ 864mm x 406mm | Black, White | Clear glass sealed unit set in moulded frame. |

| FV | Full Section Width | Full vision aluminum glass section – white, clear anodized* finish; 1/8″ (3mm), (6mm*) acrylic, polycarbonate, plain or tempered glass, or 1/2″ (13mm) sealed or tempered glass units. |

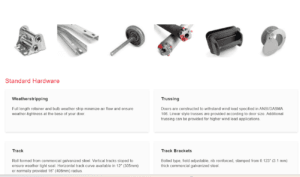

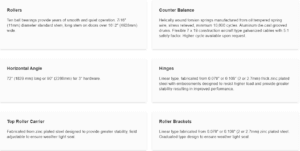

STANDARD / OPTIONAL HARDWARE

ADDITIONAL INFORMATION

Click Here for detailed specifications per model including CAD files, SpecWizards® and LEED credit information.

Click Here for detailed specifications per model including CAD files, SpecWizards® and LEED credit information.

COMPARISON

WARRANTY

Find A Dealer Near You!

A door is only as good as its installation. That’s why our doors are only installed by Authorized Dealers.

The Richards-Wilcox Difference

Since 1912